To measure Wheels, follow these key steps:

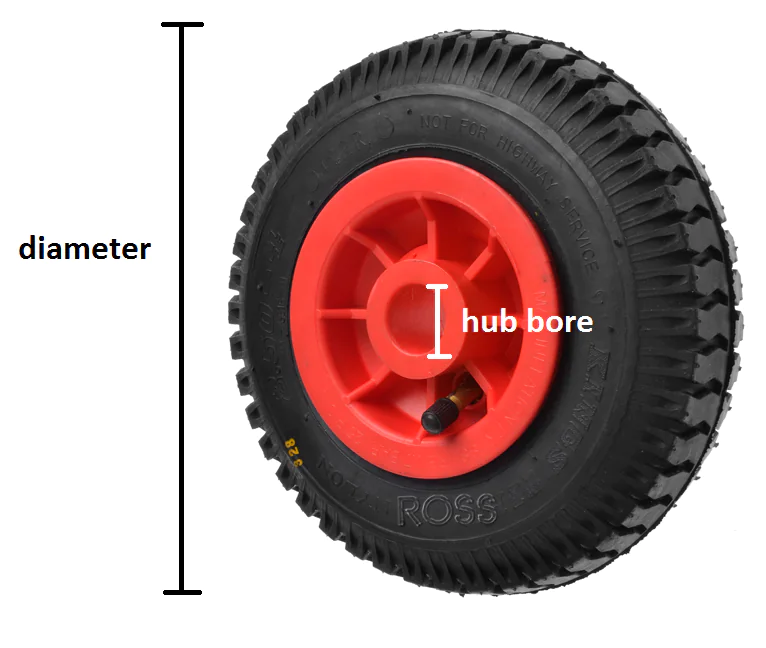

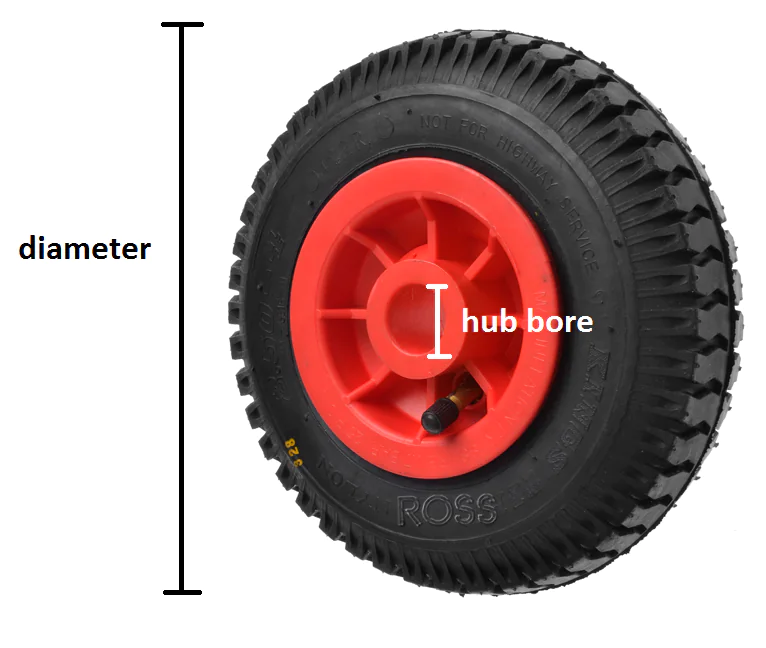

1. Measure the Wheel Diameter

The larger the wheel, the easier it is to move and the more weight it can carry. Measure the diameter of the wheel from the outside edge to the opposite outside edge. Larger wheels also help in overcoming obstacles like bumps or uneven surfaces.

To accurately measure the diameter of a wheel:

- Place the wheel on a flat surface.

- Measure from the outside edge of the wheel directly across the center to the opposite outside edge.

- Ensure that the measuring tool is aligned straight across the center for an accurate measurement.

- Record the diameter, as this will be crucial for selecting the appropriate wheel size for your application.

Understanding the importance of wheel diameter can help you make an informed decision, ensuring that the wheels you select will perform optimally in your specific environment.

2. Measuring the Hub Bore

The hub bore is the diameter of the hole at the center of the wheel and plays a crucial role in ensuring a proper fit with the axle. It's essential to measure both the hub bore and the axle diameter to guarantee compatibility. A mismatch can lead to instability, uneven wear, or even wheel failure.

To ensure the correct fit, start by measuring the diameter of your axle. The hub bore of the wheel should match this measurement to provide a secure and stable connection. This compatibility is vital for smooth wheel rotation and even load distribution, which enhances the wheel's performance and longevity.

If you find that the hub bore is slightly larger than your axle, or if you need to adapt the wheel to a different axle size, adjustments can be made. You can use bearings to reduce friction and improve load capacity, or collars and tubes to adjust the hub bore diameter for a snug fit. These solutions help ensure that the wheel remains stable and operates smoothly, even under varying load conditions.

3. Wheel Load Capacity

The load capacity of a wheel is a critical factor in determining how well it will perform under the weight of the load it needs to carry. Each of our wheels has been rigorously tested to ensure it can handle the specified load capacity, providing you with reliable performance for your application.

When selecting a wheel, it's important to consider not just the maximum load it can carry, but also the conditions in which it will be used. Floor surfaces play a significant role in the actual load-bearing capabilities of a wheel. For example, smooth and even surfaces allow wheels to carry their maximum rated load more effectively, while rough or uneven surfaces can increase stress on the wheel, potentially reducing its effective load capacity.

In addition to the type of floor surface, the frequency and intensity of use should also be taken into account. Wheels that are subjected to continuous or heavy use may experience wear and tear more quickly, which can gradually reduce their load capacity over time. Regular maintenance and inspection can help identify signs of wear early, ensuring that the wheels continue to perform as expected.

It's also essential to avoid overloading the wheels, as exceeding the specified load capacity can lead to wheel failure, potentially causing damage to both the wheel and the equipment it supports. To help you make informed decisions, each of our wheels is marked with a load capacity symbol, indicating the maximum weight it can safely handle. Always check this symbol and ensure the wheel you choose is rated for the load it will carry in your specific application.

4. Tread Width

Tread width is the measurement of the wheel's contact surface with the floor, and it significantly influences the wheel's performance, stability, and impact on the flooring. Wider tread wheels distribute the load over a larger area, providing better stability and reducing the risk of floor damage. This makes them ideal for outdoor environments or surfaces that are uneven or soft, as they help prevent the wheel from sinking and make it easier to move heavy loads across varied terrains.

In contrast, narrower tread wheels focus the load on a smaller area, which can enhance maneuverability and reduce rolling resistance on smooth, hard surfaces. This makes them suitable for indoor use where space is limited and the floor is solid. However, they may not offer the same level of floor protection or stability as wider tread wheels. Selecting the appropriate tread width depends on your specific environment and application, ensuring optimal performance and longevity of both the wheels and the surfaces they traverse.

5. Hub Length

Hub length refers to the width of the hub bore, which is the central section of the wheel where the axle passes through. This measurement is crucial because it directly impacts the wheel's stability and fit on the axle. To accurately measure hub length, you should measure the distance across the center of the wheel from one side of the hub bore to the other.

Ensuring the correct hub length is essential for smooth and secure wheel operation. If the hub length is too short, the wheel will wobble on the axle, leading to instability, uneven wear, and potential damage to both the wheel and the axle. This wobbling can also make the equipment difficult to control, particularly when carrying heavy loads or moving at higher speeds.

On the other hand, if the hub length is too long, the wheel won’t fit properly onto the axle. This can cause the wheel to stick out or not fully engage with the axle, compromising the overall functionality and safety of the equipment. A hub length that is too long may also prevent the wheel from rotating freely, leading to increased friction, wear, and potential failure over time.

6. Wheel Types

Wheels can be categorized into two types: soft tread wheels and hard tread wheels. The general principle is to use hard tread wheels on softer floor surfaces and soft tread wheels on harder floor surfaces. This principle reduces rolling tractive resistance and makes the wheels easier to move.

Hard Tread Wheels

Nylon Wheels, Polypropylene Wheels, Phenolic High Temperature Wheels, and Cast Iron Wheels are easiest to maneuver, as they have a lower rolling resistance against the floor surface. They are durable, strong, and long-lasting, depending on their application. They can, at times, be considered noisy and may damage some floor surfaces. However, these hard tread wheels remain our best sellers for everyday applications.

Soft Tread Wheels

Solid Rubber Wheels, Pneumatic Rubber Wheels, High-Temperature Rubber Wheels, and Polyurethane Wheels generally cause less floor damage, make less noise, and some are even non-marking rubber wheels. Polyurethane wheels tend to sit between the two types of wheels, as they have a hard nylon, cast iron, or aluminum center with a softer polyurethane tire bonded on. This makes polyurethane wheels some of the most versatile wheels in the range.

7. High Temperature Wheels

We offer a range of wheels specifically designed to perform in extreme temperature environments without compromising their durability or functionality. Our selection includes hard tread phenolic resin wheels and soft tread high-temperature rubber wheels.

Phenolic resin wheels are ideal for applications that require resistance to high temperatures, such as industrial ovens or manufacturing processes involving heat exposure. These hard tread wheels are known for their strength, durability, and ability to maintain their shape and load-bearing capacity even under extreme heat.

In contrast, our soft tread high-temperature rubber wheels provide similar heat resistance while offering a softer surface that is gentler on floors. These wheels are suitable for environments where both temperature resistance and floor protection are important. Whether you're dealing with high-heat industrial settings or need wheels that can withstand fluctuating temperatures, our range of high-temperature wheels ensures reliable performance in demanding conditions.

8. Bearings

There are a number of bearings to choose from depending on your wheel type, load ratings, and application:

- Plain Bearings: Wheels with no bearings.

- Roller Bearings: A bearing collar containing needle roller bearings, often the most common and well-used bearings. Most suitable for medium-duty applications, making the wheel easier to move.

- Ball Journal Bearings & Tapered Roller Bearings: Precision bearings for heavier load applications.

- Stainless Steel Bearings: Available for outdoor environments and food manufacturing plants, providing resistance to corrosion.

Conclusion

Selecting the right wheel for your specific application is crucial for ensuring optimal performance, durability, and safety. From understanding the importance of wheel diameter in load distribution and ease of movement, to ensuring a proper hub bore fit for stability, every detail plays a vital role. Considering factors like load capacity and tread width can significantly affect the longevity of both the wheels and the surfaces they traverse, while choosing the appropriate wheel type—be it for hard surfaces, soft environments, or high-temperature conditions—ensures that your equipment functions smoothly and reliably.

By paying attention to these key aspects, you can make informed decisions that not only enhance the efficiency of your operations but also extend the lifespan of your wheels and equipment. Whether you need wheels that can handle heavy loads, navigate different terrains, or withstand extreme temperatures, our comprehensive range of options is designed to meet the diverse needs of any application.

(EUR)

(EUR)