To measure Adjustable Feet, follow these key steps:

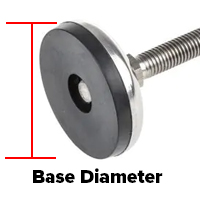

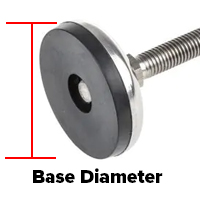

1. Measure the Base Diameter

Begin by measuring the solid structural part of the adjustable foot, known as the base. This diameter influences the overall strength and durability of the foot. A larger base diameter typically provides a stronger connection between the threaded rod and the foot, helping to bear heavier loads and ensuring stability. Accurate measurement of the base diameter is essential to ensure the foot properly supports the weight of the equipment.

2. Measure the Base Height:

The base height is the distance from the bottom of the foot to where the threaded section starts. This measurement is crucial for determining the total height the foot will add to your equipment. If precise clearance or elevation is needed (for example, leveling an uneven surface), ensure that the base height provides enough room without over-extending the thread. This helps maintain balance and prevents tipping.

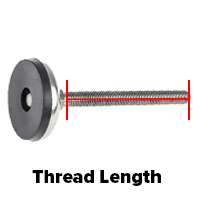

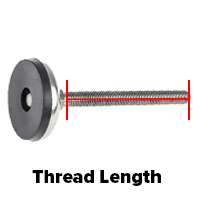

3. Measure the Thread Length:

To measure the thread length, start from the point where the thread begins at the bolt of the foot and extend to the tip of the thread. The thread length determines how much vertical adjustment is possible. For instance, longer threads allow for greater height flexibility, but be sure that the thread isn't too long for the depth of the mounting hole in your equipment, as this could compromise stability.

4. Determine the Thread Size:

Use a caliper to accurately measure the diameter of the threaded rod. Most adjustable feet use standard metric sizes like M8, M10, or M12, where "M" refers to the diameter in millimeters. Match the thread size to the corresponding thread in your equipment to ensure a proper fit. If you don’t have calipers, you can use a thread gauge or consult a chart for thread sizes based on your equipment's manual.

5. Assess Load Capacity:

When assessing load capacity, refer to the manufacturer’s data for the maximum weight each foot can support. The load capacity is influenced by the material, thread size, and foot diameter. For example, steel feet generally support heavier loads than plastic or rubber alternatives. Be sure to factor in both the static load (the weight when stationary) and dynamic forces, such as movement or vibration, which can increase stress on the feet.

| Thread Size | Outer Diameter (mm) | Standard Pitch (mm) | Common Applications |

| M4 | 4 mm | 0.70 mm | Light loads, small equipment |

| M6 | 6 mm | 1.00 mm | Furniture, medium loads |

| M8 | 8 mm | 1.25 mm | Office furniture, shelving |

| M10 | 10 mm | 1.50 mm | Industrial equipment |

| M12 | 12 mm | 1.75 mm | Heavy machinery, industrial uses |

| M16 | 16 mm | 2.00 mm | Heavy-duty equipment |

| M20 | 20 mm | 2.50 mm | Large equipment, high loads |

6. Select the Right Material:

Choose a material that matches the environment and load conditions. For industrial or outdoor use, stainless steel, aluminium or zinc-plated feet offer corrosion resistance and high durability. For lighter indoor applications, materials like rubber can provide sufficient strength while protecting flooring. Some feet feature rubberized bases to minimize floor damage or noise, which can be useful in office settings or when moving furniture frequently.

Stainless Steel

Ideal for industrial and outdoor use, stainless steel provides excellent corrosion resistance and durability. Perfect for heavy-duty applications or environments exposed to moisture or chemicals.

Zinc-Plated Steel

This material offers excellent corrosion resistance at a lower cost than stainless steel, making it suitable for indoor or light-duty outdoor applications. Zinc plating adds a protective layer, enhancing durability in environments with occasional exposure to moisture.

Aluminium

Lightweight and corrosion-resistant, aluminum is ideal for situations where strength-to-weight ratio is important. It’s commonly used in industrial and outdoor applications, as it resists rust and is easy to adjust.

Rubber

Used for feet that need to protect delicate surfaces like wood or tile. Rubber provides grip, reduces noise, and helps prevent scratches, making it suitable for furniture or equipment that will be moved often.

Conclusion

By carefully measuring each component and considering your specific application, you can select adjustable feet that provide the perfect balance of height adjustment, stability, and load capacity. These steps ensure that your adjustable feet will meet your needs, whether for industrial equipment, furniture, or commercial applications. Always double-check your measurements to guarantee a secure and proper fit for long-lasting reliability. Explore our range of Adjustable Feet and find what's right for you!

(EUR)

(EUR)