To measure a castor, follow these key steps:

1. Measure the Wheel Diameter

Measure the diameter of the castor wheel from one edge to the opposite edge, passing through the center of the wheel. This is typically the most important measurement, as it determines how easily the castor will roll and how much weight it can support. Remember, the bigger the wheel, the easier it is to move!

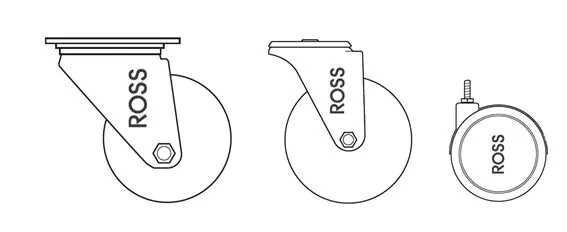

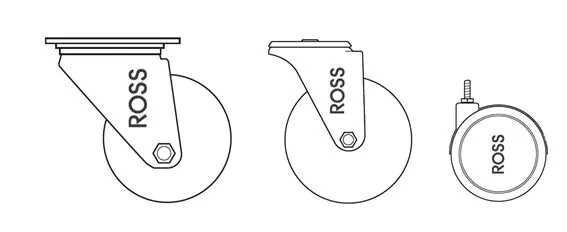

2. Choose the Castor Type: Top Plate, Bolt Hole, or Threaded Stem

Selecting the appropriate castor type is crucial as it determines how the castor will be attached to your equipment and influences its load-bearing capacity.

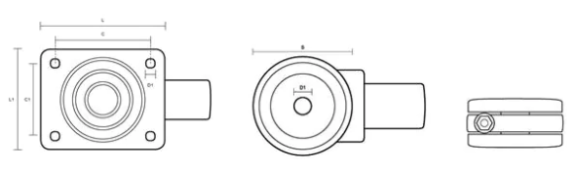

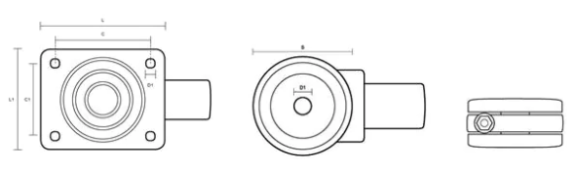

Top Plate: This type of castor features a flat metal plate that is bolted to the bottom of your unit. It provides a secure and stable attachment, making it ideal for heavier loads. Top plate castors are commonly used for equipment that requires robust support and minimal movement.

Bolt Hole: Bolt hole castors are designed with a central hole through which a bolt or screw is inserted to attach the castor to the unit. This option offers flexibility and is suitable for applications where easy installation or replacement is a priority.

Threaded Stem: These castors have a threaded stem that screws directly into a matching hole on the unit. They provide a strong connection and are often used for lighter equipment or furniture that needs to be frequently moved or adjusted.

Choosing the right castor type ensures that your equipment is securely fixed and capable of handling the expected load, contributing to both safety and functionality.

3. Fixing Dimensions

Accurately measuring the fixing dimensions is essential for ensuring a proper fit when replacing castors. If you're using a top plate castor, measure the dimensions of the plate, including the length and width, to match any replacement castors. If your castor uses a bolt hole or threaded stem, measure the dimensions of the bolt or stem. This includes the diameter and length to ensure compatibility.

For threaded stems, it's important to measure the thread size accurately. To do this, measure the diameter of the thread. For example, an 8mm diameter corresponds to an M8 thread. Additionally, if you require fixing bolts and nuts, measure the fixing bolt size (D1) to ensure we can supply the appropriate components for your needs.

4. Choose Your Wheel Material

Selecting the right wheel material is crucial for achieving the best performance and durability in your specific application. The material you choose will affect how the castor handles different surfaces, the amount of noise it produces, and its resistance to wear and tear.

Rubber: Rubber wheels are ideal for smooth and quiet operation, especially on hard floors like wood or tile. They offer good traction and are gentle on floors, making them suitable for indoor use.

Polyurethane (PU): Polyurethane wheels provide a balance between durability and floor protection. They are resistant to chemicals, oils, and abrasions, making them ideal for both indoor and outdoor use, particularly in environments where the wheels might encounter rough surfaces or debris.

Nylon: Nylon wheels are known for their strength and resistance to impact, making them suitable for heavy loads and industrial settings. They perform well on hard surfaces but can be noisy and may cause damage to softer floors.

Cast Iron or Steel: These wheels are extremely durable and can support very heavy loads, making them ideal for industrial environments. However, they can be noisy and may cause damage to delicate floors, so they are best used on concrete or similarly tough surfaces.

Pneumatic: Pneumatic wheels, filled with air, are perfect for outdoor use where the terrain may be uneven or rough. They provide excellent shock absorption and a smooth ride but may require more maintenance.

5. Castor Configuration - Swivel, Fixed or Braked Castors

When selecting castors for your equipment, choosing the right configuration is just as important as the type and size. Below are the most popular configurations, each offering unique benefits depending on your specific needs:

Four Swivel Castors: This configuration provides maximum manoeuvrability, allowing your equipment to move freely in any direction. However, it can be challenging to control on a straight path, and it may not be ideal for handling very heavy loads due to the potential for reduced stability.

Two Swivel Castors and Two Fixed Castors: This is the most popular configuration because it offers an excellent balance between control and manoeuvrability. The fixed castors provide stability and make it easier to move in a straight line, while the swivel castors allow for easy turning and positioning.

Two Swivel Castors with Brakes and Two Fixed Castors: This configuration is highly popular as it combines good control and manoeuvrability with the added advantage of brakes. The brakes on the swivel castors allow you to lock your equipment in place when needed, providing both security and flexibility in various situations.

Swivel

Swivel with brake

Fixed

Bolt Hole

Bolt Hole with brake

6. Check the Load Capacities – for a 4 Castor Trolley

Understanding the weight your castors need to support and move is a crucial consideration when selecting the right castors. To ensure safety and performance, use the following calculation to determine the maximum load each castor must carry:

Max Load per Castor = (Unit Weight + Maximum Extra Load) ÷ 3

By dividing the total load by 3, you allow for a margin of safety, accounting for uneven floor surfaces and dynamic forces that may occur during movement. This calculation ensures that each castor can handle the load effectively in a safe working environment, reducing the risk of overloading and enhancing the longevity of your equipment.

7. Other Considerations That May Affect Your Choice

When selecting castors, several additional factors may influence your decision beyond basic size and load capacity:

Swivel Radius: The swivel radius is the distance from the centre of the castor head fitting to the outer edge of the wheel. This measurement is crucial to ensure there is sufficient clearance for the castor to rotate fully without obstruction. It's particularly important to consider this when deciding where to attach the castor. Note that braked castors have slightly larger swivel radii due to the added foot brake mechanisms.

Floor Surfaces: The load ratings for our castors assume a reasonably level floor surface. Any obstructions, ridges, cracks, or debris can affect the load capacity and efficiency of the castors. It is essential to carefully choose the appropriate wheel type for your castors based on the specific floor conditions.

Health & Safety: Our castors are designed for low-speed applications. For high-speed or powered towing applications, specialised castors are available upon request. Selecting the correct castor is crucial for protecting against manual handling injuries and ensuring safe operation.

Bearings: Castors equipped with bearings offer smoother movement, but in certain outdoor or offshore environments, standard bearings may seize. For these conditions, consider stainless steel bearings, which are available upon request.

Temperature: We offer a specialised range of temperature-resistant castors that can withstand extreme conditions. These castors are suitable for high temperatures found in ovens, kilns, and foundries, as well as low temperatures in freezers or outdoor environments.

For a wide range of castors that meet these criteria, visit our Castors Page where you can explore our full selection. If you need further assistance or have specific requirements, our team is ready to help you find the perfect solution.